Heat pump systems are gaining popularity as an energy-efficient different to traditional heating and cooling methods. However, bettering their efficiency is a continuing problem for researchers and engineers. One promising resolution to reinforce warmth pump efficiency is the use of microchannel heat exchangers.

Heat exchangers play a crucial position in warmth pump systems by transferring thermal power between two fluids. Traditional warmth exchangers have been efficient in this regard, however they have sure limitations that hinder overall system efficiency. Microchannel warmth exchangers offer a number of advantages over their conventional counterparts, making them an attractive option for heat pump purposes.

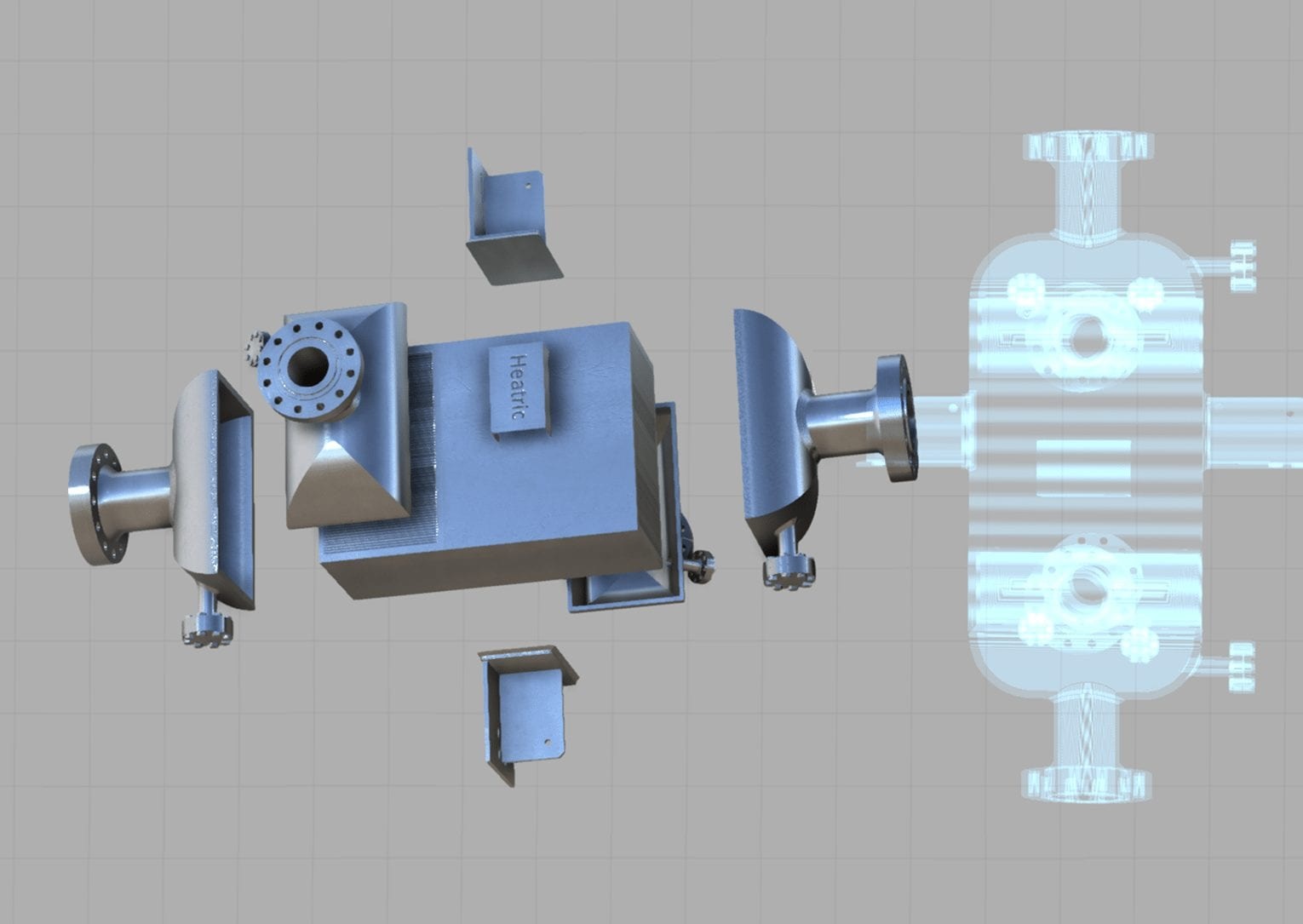

Reduced Size and Weight

One significant advantage of microchannel warmth exchangers is their compact size and decreased weight. Their design consists of multiple parallel channels, typically with hydraulic diameters under 1mm. This compactness allows for a more efficient use of space, making them suitable for installations the place space is restricted, similar to residential and commercial buildings.

The decreased weight of microchannel warmth exchangers also simplifies transportation and installation processes. With lighter parts, heat pump methods can be easily transported to various areas, reducing logistics costs and environmental impression.

Enhanced Heat Transfer

Microchannel heat exchangers present enhanced heat switch capabilities in comparability with conventional designs. The small channel sizes increase the floor space available for warmth change, selling better warmth switch charges. This increased effectivity results in improved performance and lowered power consumption of the warmth pump system.

In addition, microchannel warmth exchangers benefit from the turbulent move situations that happen at such small scales. These circumstances additional improve warmth switch coefficients, guaranteeing environment friendly warmth change between the working fluid and the encircling surroundings.

Improved Durability

Microchannel warmth exchangers are constructed using advanced materials, similar to aluminum alloys or stainless-steel, which provide superior corrosion resistance and sturdiness. This allows them to withstand harsh working conditions and maintain their performance over an extended period. The use of high-quality materials additionally reduces the danger of leakage or system failures.

Furthermore, microchannel warmth exchangers are less prone to fouling, due to their small channel sizes. Fouling happens when substances in the working fluid deposit on the heat switch surfaces, reducing effectivity. With microchannel designs, the smaller dimensions decrease the accumulation of contaminants, resulting in longer intervals between upkeep or cleansing procedures.

Potential for System Integration

The compact nature of microchannel heat exchangers opens up possibilities for system integration and optimization. Heat pump manufacturers can design more flexible microchannel heat exchanger manufacturer and versatile systems by leveraging the advantages of microchannel technology. This integration can lead to improved overall system efficiency and performance.

Additionally, microchannel warmth exchangers allow for higher management and regulation of refrigerant flow, enabling precise temperature management. This side is particularly valuable in applications the place tight temperature control is critical, similar to pharmaceutical storage facilities or laboratories.

In conclusion, microchannel warmth exchangers present nice promise in enhancing heat pump effectivity. Their compact dimension, enhanced heat switch capabilities, improved sturdiness, and potential for system integration make them a compelling alternative for heat pump purposes. As research and growth continue in this field, we will expect additional developments that may drive the widespread adoption of microchannel warmth exchangers in heat pump methods.